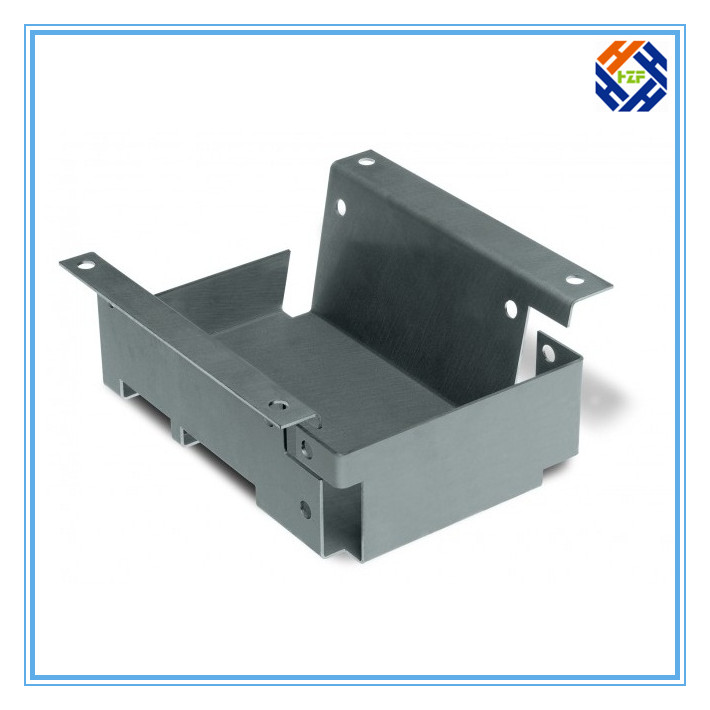

CNC Cutting & Bending

Laser Cutting Service

Sheet metal work with a CNC laser cutter

Computer numerically controlled (CNC) laser cutting is a sheet metal manufacturing process carried out by CNC laser cutters. The primary form of laser cutting for sheet metal is ‘vaporisation cutting’, in which the laser beam melts the material and a high pressure gas removes the molten material. The 3 main types of laser cutter are flying optic; moving material; and hybrid laser cutting. A flying optic laser cutter has a stationary bed for the cutting material, with the laser beam head (optic) moving in the X and Y directions above. The moving material works much like the standard punch presses, with the beam in a fixed position and the material moving in the X and Y directions beneath. The hybrid usually moves the work piece in one (X) direction, and the optic head/beam moves in the perpendicular (Y) direction.

LASER CUTTING TECHNICAL PARAMETERS

Sr. No Material Max Thickness

1 Stainless Steel Upto25mm

2 Mild Steel Upto50mm

3 Brass, Aluminum & Copper Upto16mm

.jpeg)

.jpeg)

.jpeg)

.jpeg)

.jpeg)